By Maruti Khaire

Bearings, though buried deep within a vehicle, are on the forefront in contributing to drivetrain efficiencies and delivering reliability for automotive manufacturers. However, the changing face of the automotive industry is impacting the way transmission bearings are designed and deployed.

Government policies, and stringent fuel efficiency and emission regulations along with increasing customer demand, have enabled the electrified vehicles (EVs) market to boom. Automobile industry is going through a technology transformation from ICE to EV.

This transformation is placing new specification challenges on the use of bearings, and impacting the tier one and two automotive component manufacturers and suppliers for both EVs and ICEs.

It is essential, therefore, that bearing manufacturers understand the technical challenges being faced by OEMs and Tier-1 suppliers to develop application-specific solutions that meets the demanding vehicle and aggregate technological requirements.

New challenge on bearings in EVs

Regardless of the powertrain architecture, friction is the great enemy. The push for efficiency throughout the drivetrain is prompting OEMs to explore new low-friction alternatives. The conventional transmissions and differentials utilise tapered roller bearings which are having higher friction compared to equivalent alternative bearing types.

The higher rotational speeds spur challenging and demanding conditions on bearings used in EV transmissions. Higher rotation speed of bearings is having higher centrifugal forces and heat generation, which heat them up. These bearings require specialised cage designs, internal geometry, and lubricant characteristics. Vehicle manufacturers also want them to operate reliably for the design-life of the vehicle, around ten years or 300,000 km today, and up to 500,000 km or even more in the near future.

However, speed is not the only challenge. High and fast switching voltages of the electric motor inverter bring a greatly increased risk of stray currents leakage through the powertrain components. If they pass through conventional steel bearings, such currents can damage their surfaces, leading to higher friction, increased vibration and premature or abrupt failures. That is where advanced ceramic bearings protect them from the leaking current and enhance the life of bearings in such working environments.

Solving the challenge

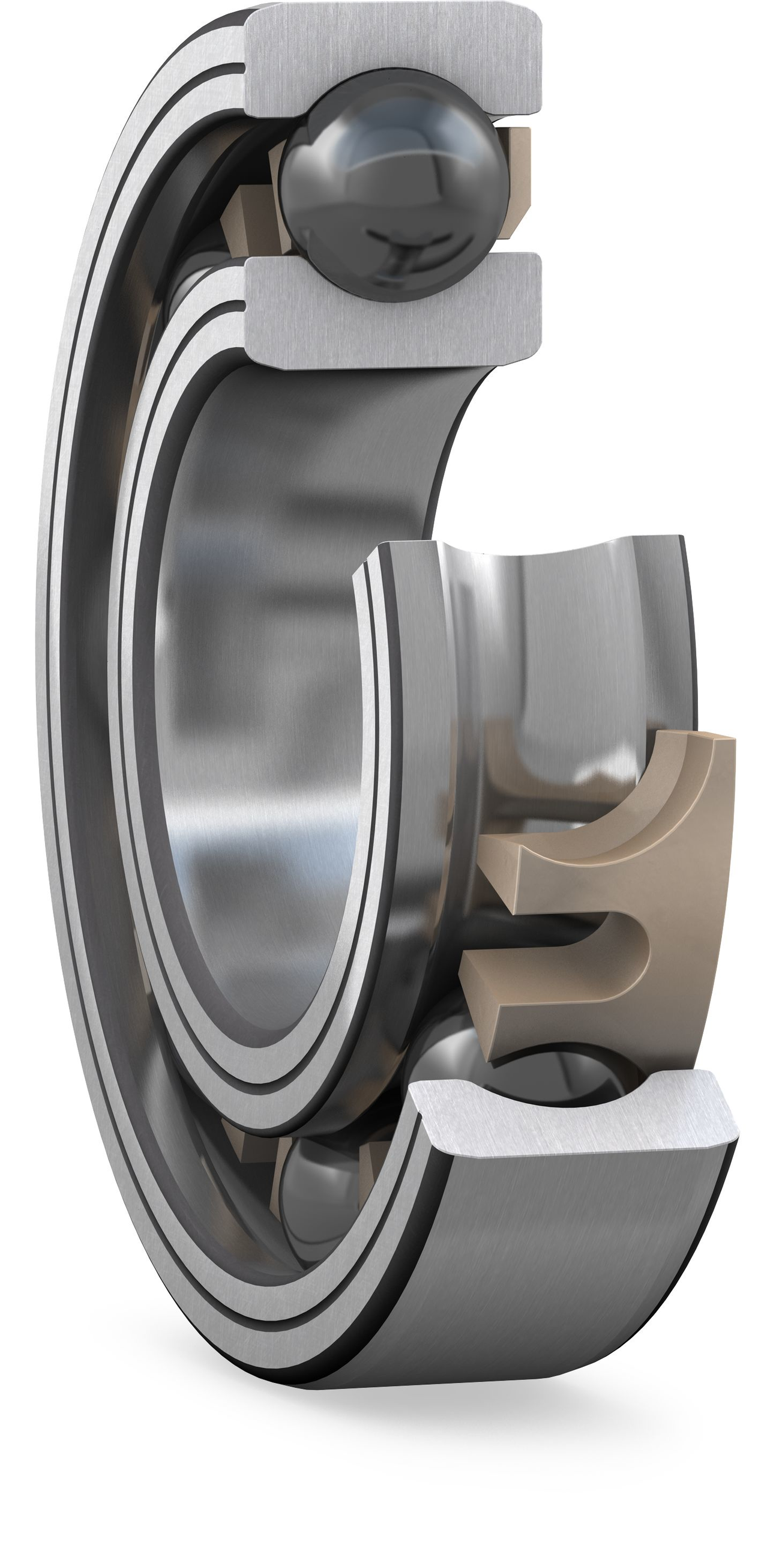

In response to these new challenging work conditions, leading bearing manufacturers like SKF are investing in new technological developments and adapting or redesigning conventional bearings. Bearing design for such demanding conditions requires system rethinking. Bearing redesign includes new considerations such as the polymer cage, rolling components and using special lubricating grease. Customised and hybrid bearings are solving some of the fundamental issues that can affect reliability of electric vehicles.

In terms of electrical discharge, ceramic ball bearings are currently the most attractive solution as ceramic is an electricity insulating material. It is also more suitable for high-speed applications than steel rolling elements.

Hybrid bearings with better performance

SKF has been helping the automotive industry to meet these challenges since the beginning of the EV revolution. Many leading OEMs in Asia, Europe and North America alike are trusting SKF bearings and solutions as part of their electric drivetrain designs.

SKF hybrid Deep Groove Ball Bearing (DGBB), for example, uses ceramic rolling elements and steel rings. Bearings of this type offer improved high-speed performance and best-in-class electrical insulation characteristics, making them the premium choice for high performance EV powertrains. In addition, SKF is also developing application-specific solutions to mitigate risk of current leakage at system level and to protect the entire EV transmission.

Application-specific engineering

Application-specific engineering and close cooperation with customers at the early phase of the electric powertrain development is key for developing a winning solution. Early involvement of the SKF engineering team allows suitable design of high efficiency bearing to meet the demanding performance specifications. SKF can support customers with solutions and design alternatives to reduce overall system power losses and therefore maximise per charge operating range of electric vehicles.

Bearings roll out EV market growth

Carmakers are set to launch around 450 new battery and plug-in-hybrid vehicle models over the next two years. Given the new constraints linked to EV technology development, the contribution of bearings to the overall system behaviour should not be underestimated. Manufacturers like SKF are determined to ensure that bearings are fit for the future with improvements in performance, efficiency, and reliability. It is believed that the future of automobiles is electric powertrain and bearings will play a pivotal role in its performance.

Conclusion

EVs are the future. Though they currently account for only a small part of the vehicle market, demand for them is building fast. EV powertrain performance can be enhanced to make them more efficient and reliable with components like bearings. Right selection of bearings designed with right specifications and manufactured consistently with right manufacturing set-up will impact powertrain reliability and performance. Leading manufacturers like SKF are geared up for this impactful journey.

(Disclaimer: The author is Head – Electrification & Special Projects, SKF India. Views expressed are personal)