New Delhi: The domestic auto sector could continue to face supply chain headwinds, especially due to semiconductor chips shortages, over the remainder of FY22. This is likely to reduce the expected sales growth for the passenger vehicles (PV) segment, and to trim profitability, India Ratings and Research (Ind-Ra) said in a latest report.

Ind-Ra expects the semiconductor chips shortage to continue to the end of the first half of FY22, though availability may gradually improve over this period, the rating agency said in a release on Tuesday.

It further expects original equipment manufacturers (OEMs) to reassess supply chains to diversify and/or partially localise their raw material requirements over the near-to-medium term.

According to Ind-Ra, the government through the launch of investment schemes has showcased heightened focus on electronics manufacturing, including semiconductors. However, as the build-up and ramp-up of semiconductor capacity is a lengthy process, any investments are likely to aid local supply chains only over the medium to long term, it noted.

Impact on domestic auto production

Semiconductors are used in various parts such as automatic headlamps, instrument gauges, parking sensors, anti-lock braking system, and infotainment system. Typically, these find larger applications in PVs than in two-wheelers or commercial vehicles. To mitigate lower availability of semiconductors, OEMs have been prioritising the use of chips in their more-profitable models, while also developing model variants with fewer accessories that require chips.

PV OEMs such as Maruti Suzuki India Limited, MG Motor India Private Limited and the Renault Nissan Alliance, among others, have also reduced production and/or taken selective plant shutdowns, due to the shortages.

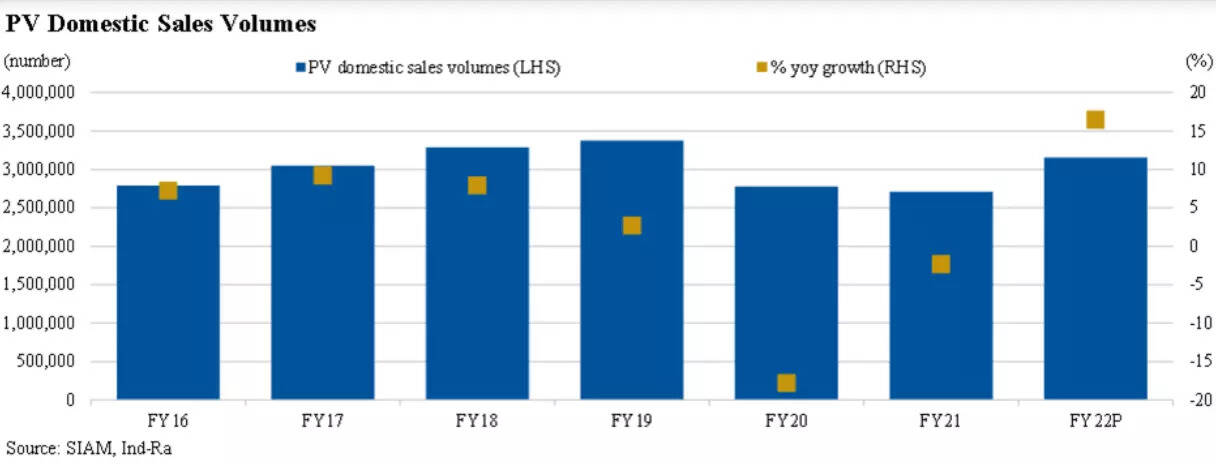

Ind-Ra believes that the demand tailwinds for the PV segment remain intact. However, the semiconductor supply scenario is evolving, and hence, the supply-side shortage could affect OEM production volumes, and thereby, the growth in sales volumes. Hence, Ind-Ra has rationalized the expected sales volume growth in the PV segment to 15%-18% from 18%-22% for FY22. The chip shortage could affect the finished vehicle inventory levels in the next few months and lead to supply-side pressures during the festive season in Q3.

Besides the increased raw material price scenario, the semiconductor chips shortage could affect the profitability of OEMs due to production disruption, and premium paid on procurement from existing/alternate suppliers to ensure adequate availability of semiconductor chips, and higher sales of non-premium models which do not require the chips in shortage.

Furthermore, Ind-Ra believes that OEMs could reassess their supply chains to diversify and/or partially localise these requirements over the near to medium term. It also expects OEMs to look at strategic investments so as to secure their supply chains, given the increasing usage of semiconductors in auto manufacturing.

Investments in semiconductors likely

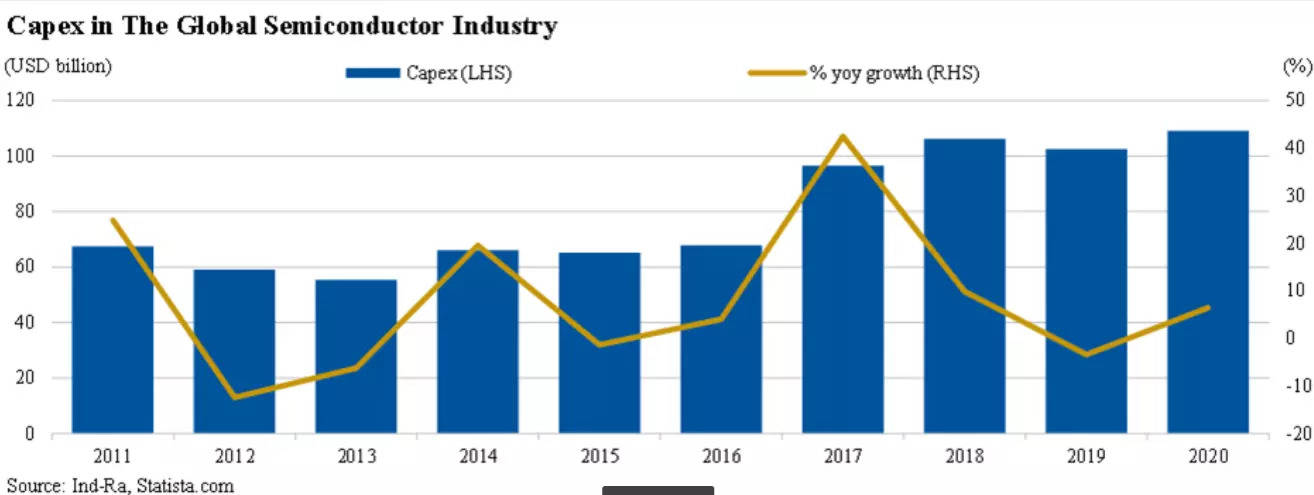

As per a McKinsey article, the global semiconductor capacity has increased by an average of 4% annually in the past two decades. Furthermore, capex growth in the global chip fabrication capacity is expected to be anywhere between 16% to 23% YoY in 2021, as per various research agencies, compared to a CAGR of 6.6% over the past decade.

The government, through the Scheme for Promotion of Manufacturing of Electronics Components and Semiconductors (2020) and the Production-Linked Incentive Schemes (2020-2021), has showcased a heightened focus on electronics manufacturing, including semiconductors.

Ind-Ra expects these initiatives to lead to the creation of a favourable environment for large-scale electronics manufacturing in India. However, semiconductor fabrication is a capital-intensive investment and the capacity requires almost two years for building. Hence, any investment is likely to aid the local supply chain only over the medium-to- long term.

Also Read: