New Delhi: With an aim to underline its system expertise in electromobility and provide electric cars with a greater range, German Tier-I supplier ZF on Thursday unveiled its self-developed thermal management system for electric vehicles (EVs). The technology giant also showcased electrification solutions for all categories of vehicles, including commercial vehicles and construction equipment.

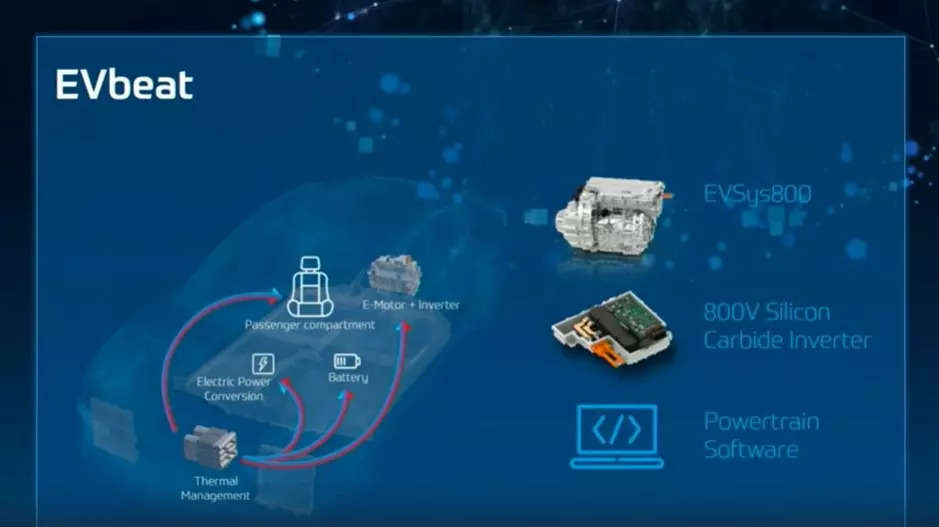

At its annual Global Technology Day demonstration event held at the headquarters in Friedrichshafen, Germany, the company showcased its technologies via EVbeat, which is a concept electric vehicle (EV) based on a Porsche Taycan.

In the concept vehicle, ZF said the unique thermal management system offers more compactness in EV drivetrains, consisting of power electronics, motor and reduction gearbox based on 800-volt silicon carbide. When compared to the existing technology, the new system claims to increase the real-world vehicle range by 1/3rd at cold temperatures around freezing point during winter.

The company has developed a powertrain software to improve efficiency and enable connectivity to the Cloud. It stated that the new powertrain is free of heavy rare earth elements and can be used flexibly by car manufacturers owing to its modular design.

Also, the components of the electric driveline have been optimized and the drive package has a 30% lower overall weight to enable a torque density of 70 Nm per kg, which it claims is a record for road-legal passenger cars.

The first technologies of the new ZF driveline is expected to be available in the market 2026 onwards.

“Just a few months ago it was only a vision, now our drive can be experienced in a sports car,” said Dr. Holger Klein, CEO, ZF.

With a move towards electrification, the company which used to get over 60% of its revenues globally from the ICEs almost a decade back, now gets only about 27% specifically from ICE commercial vehicle segments, Klein said at the company’s virtual press conference.

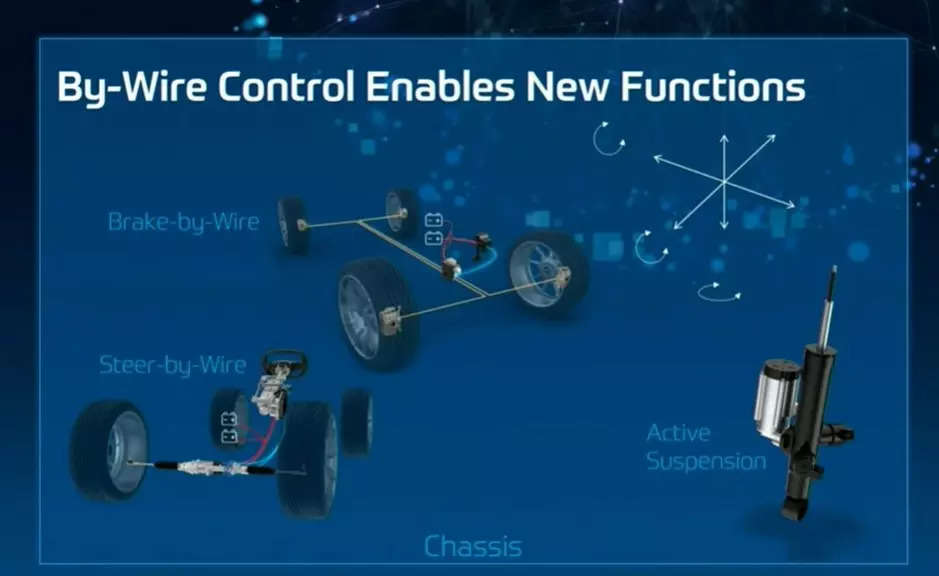

The company also offers the all-electric Steer-by-Wire steering system, for which it has received customer orders from all major world markets.

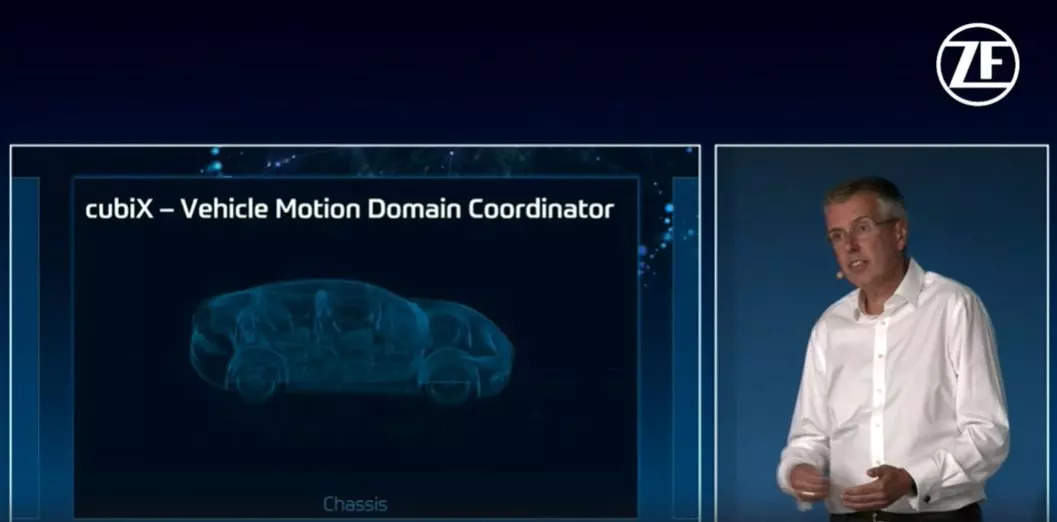

The automotive technology giant said that the cubiX chassis software, which is the first-generation 800-volt electric drive, will also be available to use for automotive manufacturers from Asia, Europe, and America in their vehicles in the coming months.

To launch Chassis Solutions division in Jan 2024

ZF also plans to merge the divisions for passenger car chassis technology and active safety technology to form a new and comprehensive Chassis Solutions division. The launch of the new division, which will consolidate the company’s braking, steering, and suspension domain expertise under a new unit, is planned for January 2024 along with a new management team.

According to Klein, “The Chassis Solution division offers all the hardware components needed to control a vehicle’s vertical, longitudinal and lateral dynamics – and also the associated networking in the form of hardware and software.”

“The unit already combines an annual turnover of more than 14 billion euros and will be a reliable and competent partner for our customers in all regions of the world,” he said.

Further, ZF said it is developing new middleware software solutions by forging stronger partnerships. Earlier, it partnered with India’s KPIT Technologies to jointly develop a middleware solution for the mobility ecosystem. The partnership evolved to the creation of a new company, Qorix, with both partners having equal equity stake in it.

The growing software defined vehicle (SDV) trend is fuelling the need for more advanced software technologies, with middleware technology being a growing part of it. Recently, Tier-1 supplier and engineering company Magna International has also identified two companies in India, with which it will collaborate for middleware technologies.

The long term goal is to use technology to make the mobility of the future clean, safe, comfortable, and affordable for everyone.