CNH is targeting significant growth over the next five years, with plans to double its market share in the tractor segment. Currently holding a 4.1% market share, the company sold approximately 37,000 tractors in India in 2024, along with exporting 10,000 units to over 70 countries worldwide. The company recently celebrated a production milestone of 7 lakh tractors in India.

Narinder Mittal, President and Managing Director, CNH India, said, “If we double our market share, we aim to reach 100,000 tractors every year within the next five years.” This projection speaks to CNH India’s strategy to increase its footprint in both the domestic and export markets, with a focus on performance-driven tractors in the higher horsepower segments.

Production and dealer network

Mittal told that the company’s strength lies in the 50 horsepower and above tractor segments. The focus on high-performance machines is helping New Holland gain a stronger foothold in India’s agricultural sector, which remains one of the largest and most important in the world.

In 2024, CNH India’s total turnover stood at around INR 7,500 crore, with tractors contributing around 65% of the business. The company’s plants in Noida and Pune currently have a combined capacity to produce 70,000 tractors per year. However, Mittal noted that they are working to increase production capacity to 100,000 units annually to meet growing demand.

To support this expansion, CNH India is also focusing on its dealer network. “Currently, we have around 500 dealers for New Holland tractors, and we plan to expand this to 800 in the next two years,” Mittal shared. This expansion is crucial as the company seeks to penetrate further into the Indian market, especially in rural areas where the demand for high-performance agricultural machinery is on the rise.

Digital transformation

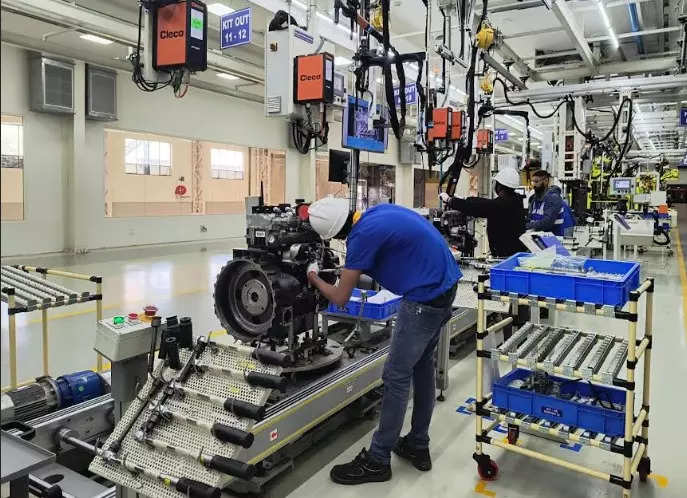

CNH India is part of a network of 42 plants worldwide, with the Indian plant operating at standards that are as strong, if not better, than others in terms of digitalisation. This global approach to innovation and digital integration has positioned CNH India to stay competitive while maintaining a strong focus on quality.

According to Mittal, the company recognised early on that digitalisation was essential, despite their focus on off-road vehicles. “Even though we are in the off-road vehicle business, quality always remains paramount for our customers,” he noted. As such, CNH India began implementing digital practices across its plant to ensure they stayed ahead of the curve in a rapidly evolving industry.

He emphasised the plant’s commitment to integrating advanced technologies, stating that their factory is equipped with artificial intelligence (AI). These technologies play a critical role in enhancing operational efficiency. “We have AI implemented that captures data from machines, and we’ve installed sensors that notify maintenance teams when conditions such as temperature rise above normal. This proactive approach ensures components don’t fail unexpectedly.”

These innovations are already yielding results in the form of increased operational efficiency and proactive maintenance systems. “The technology embedded in our products will continue to evolve, and we are confident that it will drive further growth in the coming years,” Mittal concluded.