New Delhi : Six months ago, when a Mercedes-Benz team drove the Vision EQXX from the headquarters in Stuttgart, Germany, to Silverstone, the UK, a team of engineers at the Bengaluru office also had reasons to cheer. Not that they developed the concept car, but because they had a hand in at least a few tens of KMs in the 1202 km distance covered in a single charge.

What made the achievement sweeter for the Mercedes-Benz Research & Development India (MBRDI) engineers was that they were thrown the challenge of improvising an almost complete project of the EQXX, which also reflects Mercedes-Benz’s plan to go all electric by 2030.

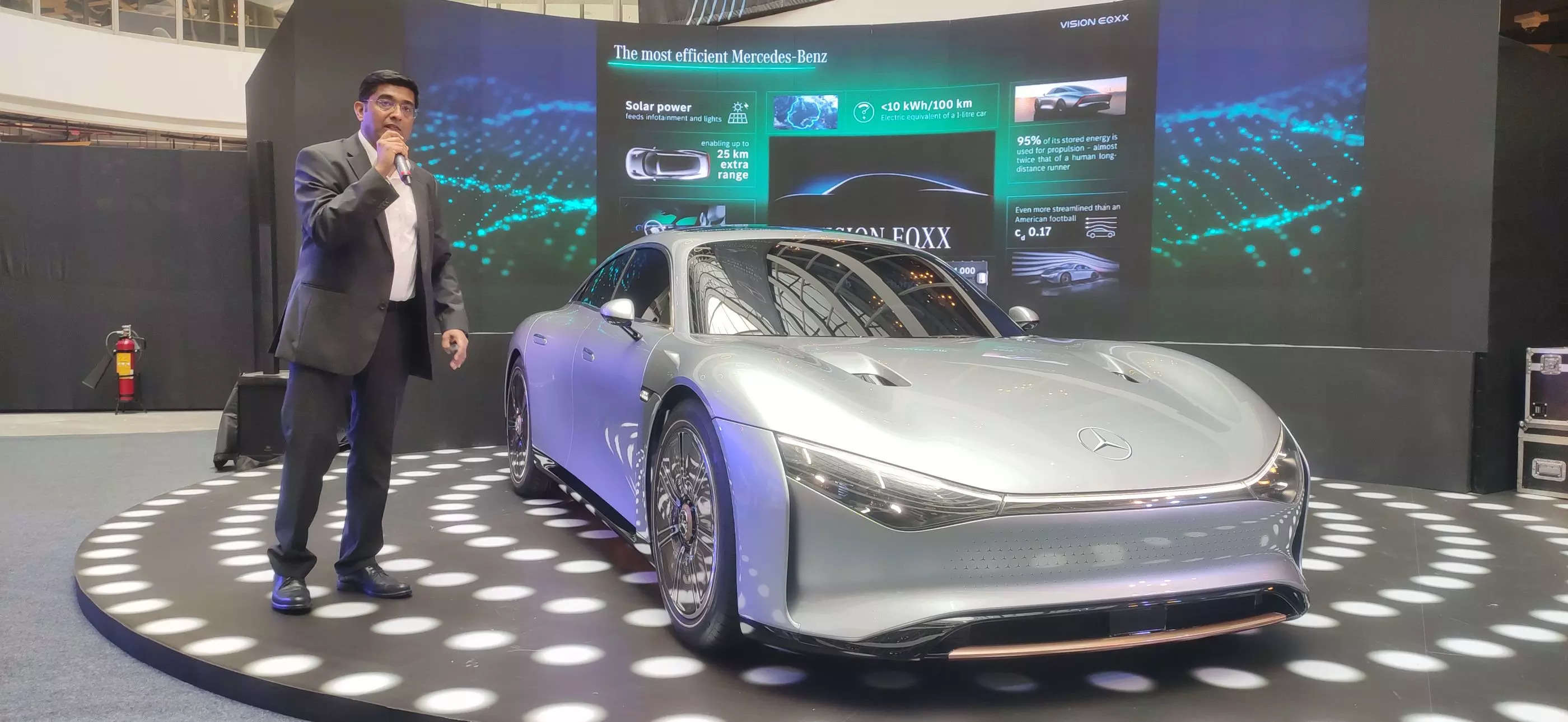

Even though a thousand kilometres in a single charge may be impressive, the extra kilometres of driving range helps address a key issue of range anxiety of many EV users and can therefore be a comfort factor. “You can say that the comfort factor of the last 40 KMs or so (in the EQXX drive) came from India,” Manu Saale, MD & CEO, Mercedes-Benz Research and Development India, toldETAuto. The EQXX was showcased for the first time in India, on Tuesday, as part of the 3rd edition of MBRDI’s Safe Roads India Summit.

The EQXX Challenge

Even as the EQXX project was close to its design finalisation, Mercedes-Benz decided to challenge MBRDI to further optimise the car ‘as much as possible’. One of the candidates for further optimisation was the front bumper. The team is learnt to have designed an even more efficient air curtain and air breather combination, which contributed to the car’s overall drag coefficient of 0.17. That intervention alone is learnt to have contributed 10KMs to the EQXX’s driving range.

The wings and mirrors were also optimised further by the team which was also tasked with the car’s architecture study.

MBRDI, one of the growing number of GCCs (Global Capability Centre) in India, has established itself as a contributor to almost every Mercedes Benz model in recent times. It specialises in digital mechanical services like CAD (Computer Aided Design), and CAE (Computer Aided Engineering).

A growing role in Mercedes-Benz’s global network of 6 engineering centres is reflected by the GCC adding a second campus, with 6,000 seats, in Bengaluru. A satellite office in Pune focuses on interior component designs and IT engineering. According to Saale, the overall team strength currently stands at 7,500 engineers, and an additional 4,000 are engaged on contractual basis.

Some of these engineers also worked on optimising the EQXX’s motor design to improve efficiency through strength simulation, as well as the car’s battery geometry optimisation. Other areas of optimisation were in weight, and NVH in some parts of the car.

Lightweighting is an evergreen topic in the automotive industry. In the evolving electrification era it’s even more sensitive, as every gram saved results in some level of extra driving range. The already lightweight wiper system of the EQXX was also a part to be optimised by the Indian team.

In addition to the digitally enabled physical engineering, MBRDI also helped create a digital platform to develop and validate the EQXX’s range calculation based on real time data.

Expansion and challenges

Though a serious challenge, the EQXX, Saale said, “is a natural development of the technology and talent investment that we have already done over the years”. For any GCC, it’s critical to have a proper positioning in the network in order to bag major projects. Else, the key competing factor may be just the cost parameter. “Over the years, I think strategywise we have been trying to find a sweet spot for where we will fit the bill globally,” says Saale. That seems to be paying off for MBRDI.

As the organisation reaches a critical level of importance in Mercedes-Benz’s projects, it plans to add over 1,000 engineers in 2023. Apart from meeting the growing demand from Mercedes-Benz’s headquarters, it will also have to address the challenge of finding the right talent. As India grows in stature as a major engineering hub, some industry leaders say that there will be a major challenge, and competition among organisations in talent hiring.

Unlike in the journey so far for MBRDI, Saale is also preparing for an era in the industry which will be technology-wise “super dynamic”. In other words an industry where technology trends will change much faster than ever before, requiring organisations to be agile enough to keep up with the times.

For now, MBRDI plans to expand its capabilities in AI (Artificial Intelligence), AR (Augmented Reality), and VR (Virtual Reality). “I think there’s a lot more you can expect from those technologies within the car, and outside the car,” says Saale, who feels that the next 5 years are going to be very exciting for technology in the industry. And more challenges like the Vision EQXX project could come MBRDI’s way to meet. Therefore, attracting and retaining the right talent will be crucial.

Also Read: