To make or not to make. If the Bard would allow this one indiscretion, this is a question that has plagued India Inc for decades. Factors like cost of production, quality and demand have together tilted the scales, often in favour of imports. Now, with the push for Make in India, there is a renewed focus on manufacturing at home, as against assembling or importing. While this has advantages across the value chain, it has large disadvantages too.

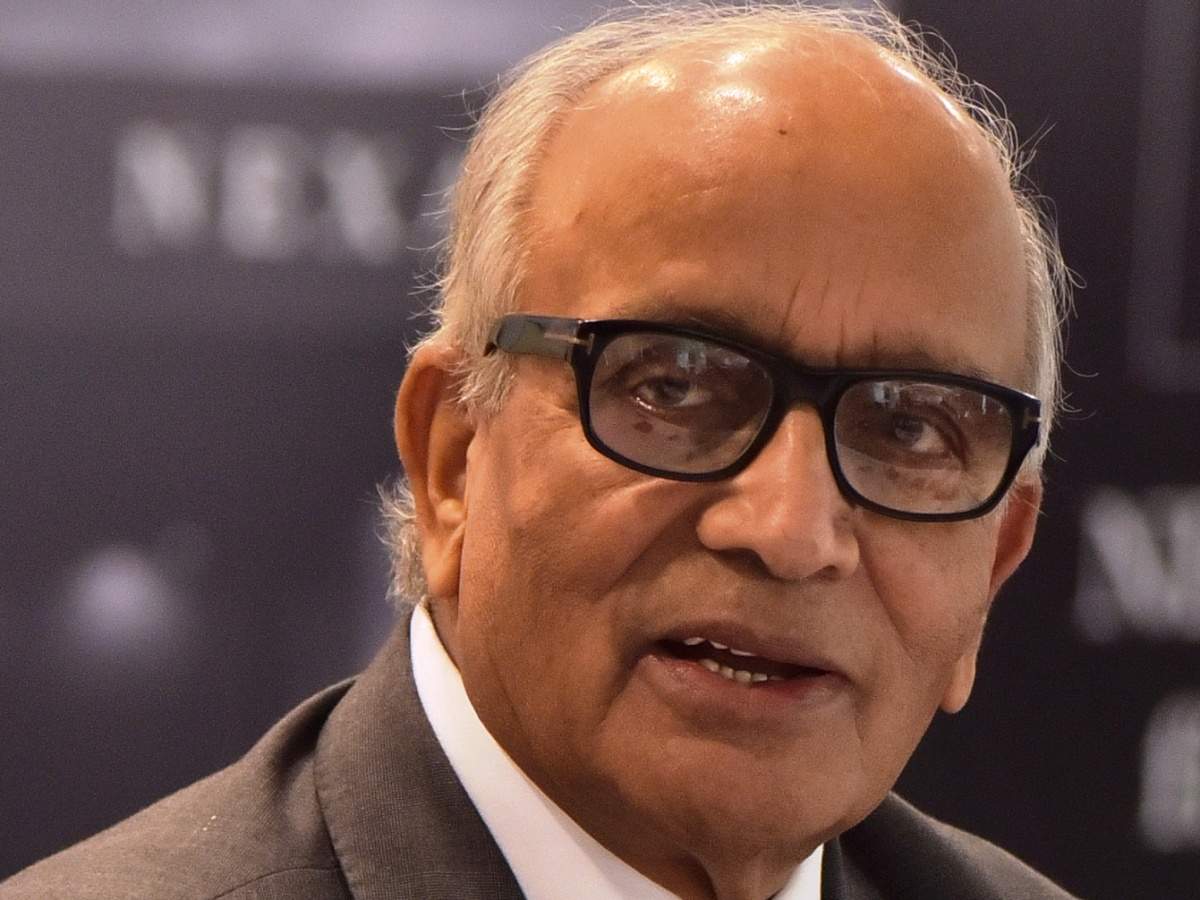

In a discussion on this issue at the ET India Inc Boardroom, R.C. Bhargava, Chairman, Maruti Suzuki India, said the biggest hurdle for manufacturing in India is high costs.

The ET India Inc Boardroom brings together industry leaders, policy makers and economists to discuss and deliberate key sectors of the economy. Over the five-day conclave, experts will uncover trends and challenges in the BFSI, Retail, Manufacturing and MSMEs sectors, as well as the economy as a whole.

“Where I think we went wrong was in thinking that you could look after the poor people by increasing the cost of manufacturing and industrial activity in India, because that made the cost of manufacturing high. We became less than competitive, it deterred foreign investors from coming into India. Higher costs of production, plus higher taxes, which were levied on a lot of items which are manufactured resulted in demand being kept down.”

Edited excerpts from a fireside chat with KPMG’s Neeraj Bansal:

Neeraj Bansal: The Union Budget is an important milestone. It’s a forward-looking growth centric, capacity building and debt-funded budget aimed at securing long-term economic growth and global competitiveness. The government has also prioritised an aggressive approach with sizable investments in healthcare and infrastructure that carry a high multiplier and will help to ease the stress on the banking sector.

The budget also unveiled a significant recheck in basic customs duties to promote domestic manufacturing. How do you see the Indian manufacturing industry trending over the next 12 to 18 months?

RC Bhargava: Indian manufacturing, for decades, has been operating at a growth rate of 6-8% a year. I think we’ll get back to it by the end of this year. But the real issue is that it is not enough, as the finance minister said in the budget speech. A double-digit growth in manufacturing is required if the $5 trillion economy target is to be met.

Manufacturing in India was high-cost and not really competitive. If there is strong competition, you will make all efforts to improve your products, reduce your costs. That has not happened. Only a few sectors such as telecom and auto became competitive, and that has led to products in India being world class, but those are very limited sectors.

Neeraj: In the auto industry, there is a lot of push from the government on domestic manufacturing. I think this budget will be revisiting some of the custom duties across several products, including auto components. This is likely to force companies in your industry to reduce their import dependency on other countries. How do you see the industry responding to this?

Bhargava: Customs duty to reduce import dependency is by itself not adequate. There are various reasons why people are importing. One, that particular products are not available in India. Nobody is making it in India because technology is not available. Also, the scale of demand in India is too small to make it economical. There is no point in import substitution if the locally made product is 30% or 40% higher in cost.

The selection of customs duties for promoting local manufacturing has to be very carefully and selectively done and used as a means of nurturing a new domestic industry.

Neeraj: What are the measures which, if are taken together, would create a good strong impact to promote domestic manufacturing?

Bhargava: The key to a lot of ‘Make in India’ lies in creating an assured demand visible to investors in the future. Today, that is unfortunately not there. Data for growth of the car industry shows the compound annual growth rate of car sales in India has declined from 10% a year, to 1.5% in the last five years. If you want to create the infrastructure for Make in India, you have to create the demand for Made in India products.

The second part is the supply chain. No manufacturer makes 100% of any product himself. In the car industry, we buy 70% of the components from various suppliers. The supplier then has his suppliers and the total number of people in the supply chain runs into thousands. All of them have to be of the same quality, cost and competitive.

Also Read: Manufacturing – to make India a hub, technology, policy could be the drivers