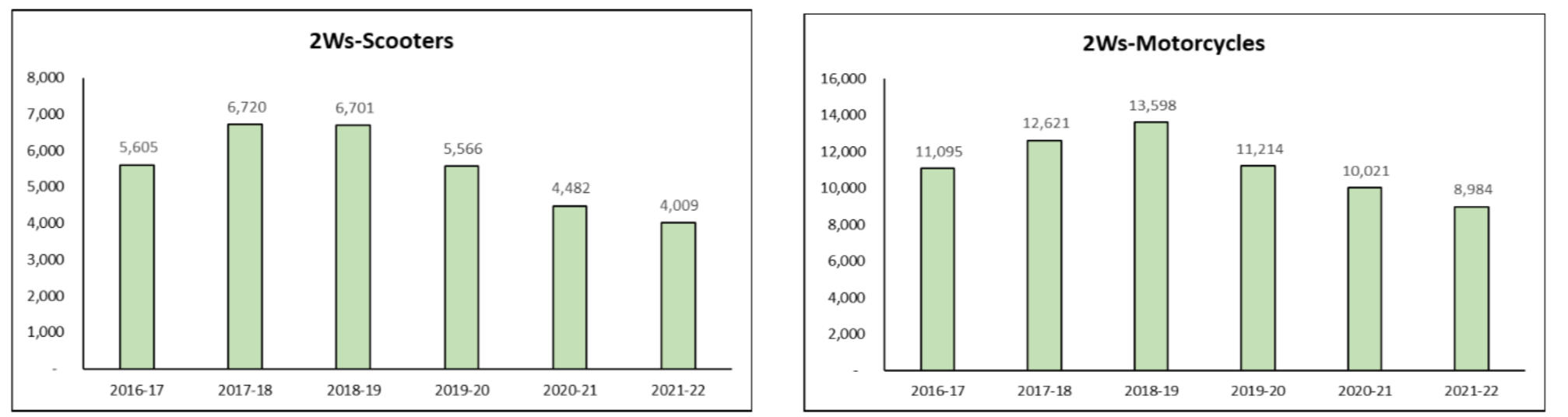

Two-wheelers, the worst-hit segment, declined to a decade low in 2021-2022 to 13,466,000 units. It was in 2011-2012 that the two-wheeler sales were close to this number at 13,409,00. In the peak year FY19, the nation’s two-wheeler market was at over 21 million units.

The deficit in the ICE two-wheeler is incredibly wide even after adding the electric two-wheelers, including low-speed and high speed, which were at about 3 lakh units. ICE three-wheelers volume also remained at 260,000 units, less than 50% of the peak volumes, while the total installed capacity is over a million units. The electric vehicles are catching up the fastest in this segment with almost 35% penetration.

Some parts of the industry have found a solace in exports. The passenger vehicles exports rose to 5.76 lakh units in FY22 compared to 4.4 lakh units in FY21.

However, export of PVs is the lowest since 2013-14 when the Indian manufacturers exported 5.96 lakh units, posing a major question on the make in India, at only about 60% capacity utilisation. Two-wheeler industry performed better in exports at 4.4 million units.

According to ETAuto Research, India has an installed automobile capacity of about 35.5 million units while only 22.9 million automobiles were produced in FY22. Only about 3.6 million passenger vehicles were produced against the installed capacity for over 7 million units.

In percentage terms, an estimated capacity utilization for four- wheelers, including commercial vehicles, in 2021-22 was 63.64% while for two and three-wheelers it was at 60.89% in FY22.

An idle capacity translates into job cuts and reduction in job creation and investment which naturally clogs the wheel of the economy. At least five automakers (Ford, Harley Davidson, MAN Trucks, UM Motorcycles) exited manufacturing in India in five years, while only two new manufacturers started operations here in the same period.

The bruise to the economy is not a blip of the past year but the result of a sequential crises created in the past 5 years.

About the outlook for financial year 2022-23, Hemal Thakker, Director, CRISIL Ltd (A S&P Global Company), said, “Incomes of people in the upper and upper middle- end of the income pyramid are better than that in the FY20 levels and hence, barring entry-level cars, all other segments will see good growth in FY23 in comparison to FY22.”

Expecting FY23 to be better than FY22, Vinkesh Gulati, president Federation of Automobile Dealers Association (FADA), pins hope on the first set of normal forecasts for monsoon as a sign of relief to the rural customer as crop yield will be normal.

With the Covid vaccination drive, people will be more immune this time around thus saving on their healthcare expenses. All these will definitely help in uplifting the mood thus helping to increase sales of tractors, entry level 2Ws and cars, he added.

As an optimist, I hope things will get better this year. However, there are six unwieldy factors that will be to industry’s consternation. They are: Rural distress, Fuel price-led inflation, Steep hike in commodity prices, Container shortage and increasing logistics cost, Chip shortage, and Multiple and duplicate bookings.

Rural Distress

In the Covid-19 first wave, India’s recovery came via Bharat with strong demand in the rural market. However, the second wave hit the rural markets equally and the impact became obvious.

About the outlook for rural market performance in FY23, Gulati said, “There are two major worries, unemployment and inflation. The government is increasing its spending on infrastructure and allocating higher budgets. It depends on the actual spending and how fast it could hit its target thus uplifting the sentiments of a rural consumer.” Despite all efforts, farmers’ income has not increased to its desired levels. So, anything which the government does to improve the income of the farmers will be a welcome step for the auto industry, he added.

Tractor, which was the only segment to stand strong for a long period in a post-corona depression, also joined the declining trend since August 2021.

Except for October when it was flat, for all the seven consecutive months the sales dipped by double digit going as high as 30% which portends long economic challenges.

Domestic sales of tractors declined by 17% in August, by 15% in September, remained flat in October, by 22.5% in November, and by 23% in December. In January and February, it fell by 33% and 31.3% respectively, and in March by 27%.

The decade low demand for motorcycles (below 9 million) and declining tractor sales for the past few months foretells a grim situation ahead for the country. In the passenger vehicle segment, the demand for utility vehicles for the first time ever surpassed that of overall cars and especially of the entry level ones mostly popular in the rural areas.

Two-wheeler segment will face another challenge as On-Board Diagnostics II (OBD II) will be implemented from April 1, 2023 that will further increase the acquisition cost. According to CRISIL research it will lead to an increase in two-wheeler prices by about 6%-7% which will be over and above intermittent price increases that we will see through the year on account of increased metal prices on account of ongoing geo-political scenario.

“Rural incomes are under pressure and increasing inflation will further reduce their ability to spend on discretionary items. Rural share in the passenger car segment came down from about 41% in Q1FY21 to about 38% in Q4FY22,” Thakkar said.

Increasing bruises to the rural economy continue as the demand for minimum wages consistently rise. As per the data from RDPR, the number of person-days generated across India has gone up from 233 in 2017-18 to 355 in 2021-22. What stimulates the pang among many other factors is the reduction in the allocation for MNREGA to INR 73,000 crore in FY23 from INR 111,500 crore in FY21.

Fuel price-led inflation

In June 2021, for the first time, petrol and diesel prices reached INR 100 mark and since then it has been hovering over INR 100 in most parts of the country.

In some Cities like Mumbai, petrol costs INR 120.51 / litre, diesel costs INR 104/ litre. The latest spike is due to the increase in the crude prices in the international market. But it has been a long-term challenge mainly because it has been attracting massive taxes. Even when the crude prices were at an all time low to almost USD 30/barrel. The combined tax (State and Central taxes, cess) on fuel was as high as 65% of the total prices.

The government of India’s tax collection sharply rose by almost 300% between 2014-15 and April-January 2021 on petrol, diesel and natural gas, according to an answer given by Union Minister of State for Finance Anurag Thakur in the Lok Sabha. Almost similar hikes have been in the state government’s tax collection from fuels. For example, the highest is in Madhya Pradesh which levies INR 31.55 a litre VAT on petrol.

On the contrary according to Moody’s Investor Service report since November 2021, state-owned refining and marketing companies have together lost about INR 17,000 crore in revenue on petrol and diesel due to non-revision of prices.

Excise duty on petrol has gone up from INR 9.48 per litre in 2014 to INR 32.90 a litre presently. For diesel, this increase is from INR 3.56 a litre to Rs 31.80.

Since March 22, after the recent elections in UP and other states, the government has increased fuel prices 14 times accounting for about INR 10/litre till April 5. Opposition parties claimed that the Government of India mopped up INR 2600,000 crore from excise on petrol and diesel since 2014.

Eventually, the Consumer Food Price Inflation for India as a whole (including rural and urban) went up to 7.68 % in March 2022, from 4.87 % in March 2021.

Fuel prices are very crucial to inflation. According to the All-India Consumer Price Index (CPI) data released by the National Statistical Office on April 12, Consumer food price has gone up by 100% between March 2021 and March 2022.

The consumer food price inflation for rural areas was 3.94% in March 2021. It went up to 8.04 %in March 2022. Similarly, the CPI for rural India has also gone up to 7.66% in 2022, from 4.61 % in March 2021.

Looking at month on month, the rural food inflation in March has also registered a steep hike in comparison to February 2022. It went up to 8.04 % in March, from 5.81 % in February. Going forward looking at the lingering Russia-Ukraine war the fuel price may go up. However, it is to note that India has managed to secure a tiny share of crude at a much less cost than the global average price due to the sanction.

Steep hike in commodity price

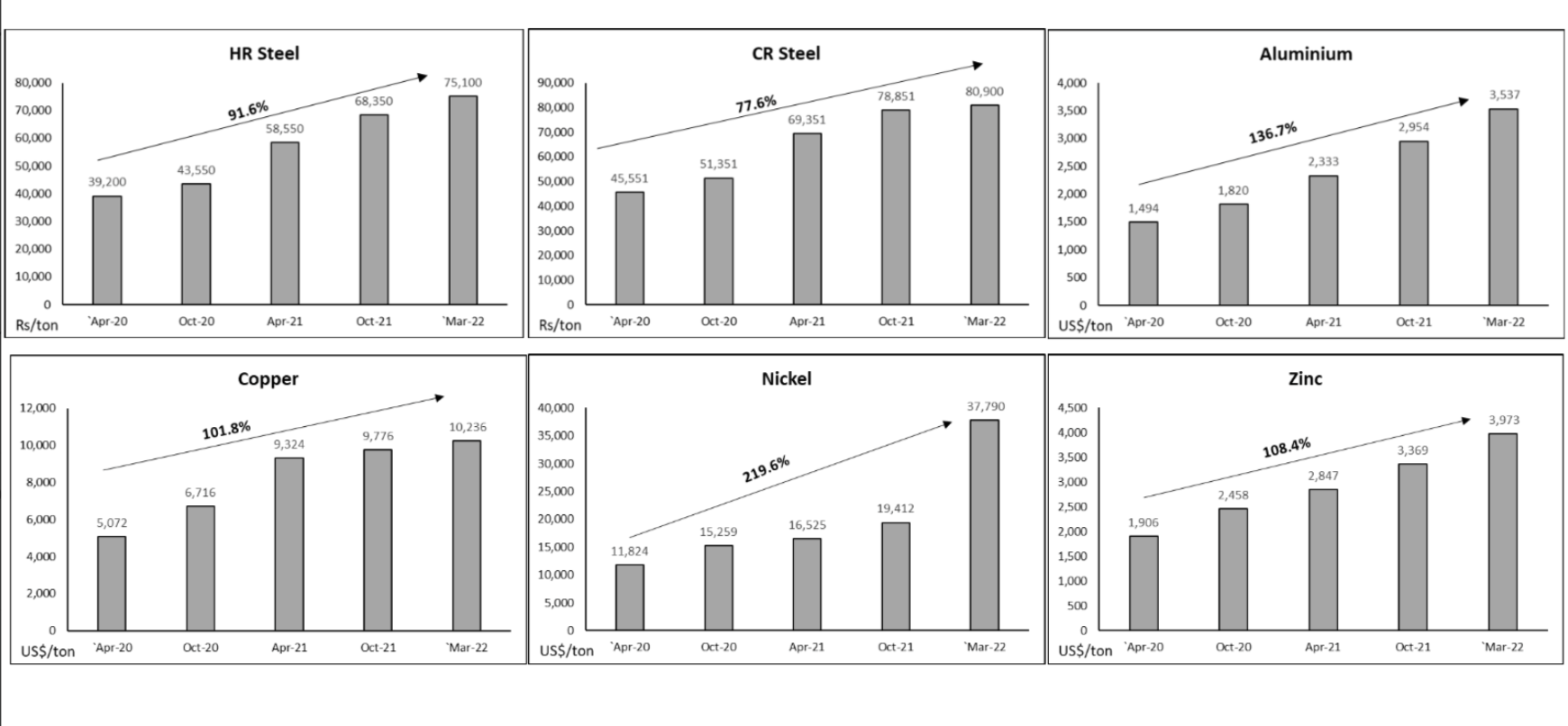

For automakers raw materials are a major cost component and for the carmakers, this is almost 75% to 78% of the cost. An increase in the cost of raw materials directly impacts the acquisition cost and demand.

Owing to the recent geopolitical problems, the price situation continues to be uncertain. The prices of the key commodities of steel, plastics, aluminium, copper, rhodium, platinum, etc have been stubbornly high since 2020.

Between April 2020 and March 2022, the prices of key commodities like Nickel, Aluminium, Zinc, Copper, HR steel and CR Steel jumped by 219%, 136%,108%, 101% 91% and 77% respectively.

In the same comparative period, the prices of precious metals which are mostly used in automotive electronics have maintained a similar upward trend.

The prices of Rhodium, Platinum and Palladium have gone up by 124%, 38.2% and 22% respectively. Since they are precious metals the cost implication is even much higher. The usage of these commodities is increasing as the vehicles are becoming more and more feature rich. The biggest challenge is that there is no positive indication of the price coming down anytime soon.

Following this most of the carmakers have introduced over 4-5 price hikes in the last one year. For example, country’s largest carmaker Maruti Suzuki has already taken 5 price hikes totalling over 9% since January 2021. It is the highest-ever price hike by the carmaker in a year.

“Increase in vehicle prices over the last 2 years have been in excess of 25%-30%,” Hemal Thakker said.

“Risk factors like inflation and consequently the possible interest rate increases and tighter liquidity. Apart from the above the possibility of Covid related disruptions and the possible adverse effect of rise of cost of acquisition due to commodity prices going up or cost of statutory regulations,” Shashank Srivastav, senior executive director (sales & marketing) Maruti Suzuki India, said.

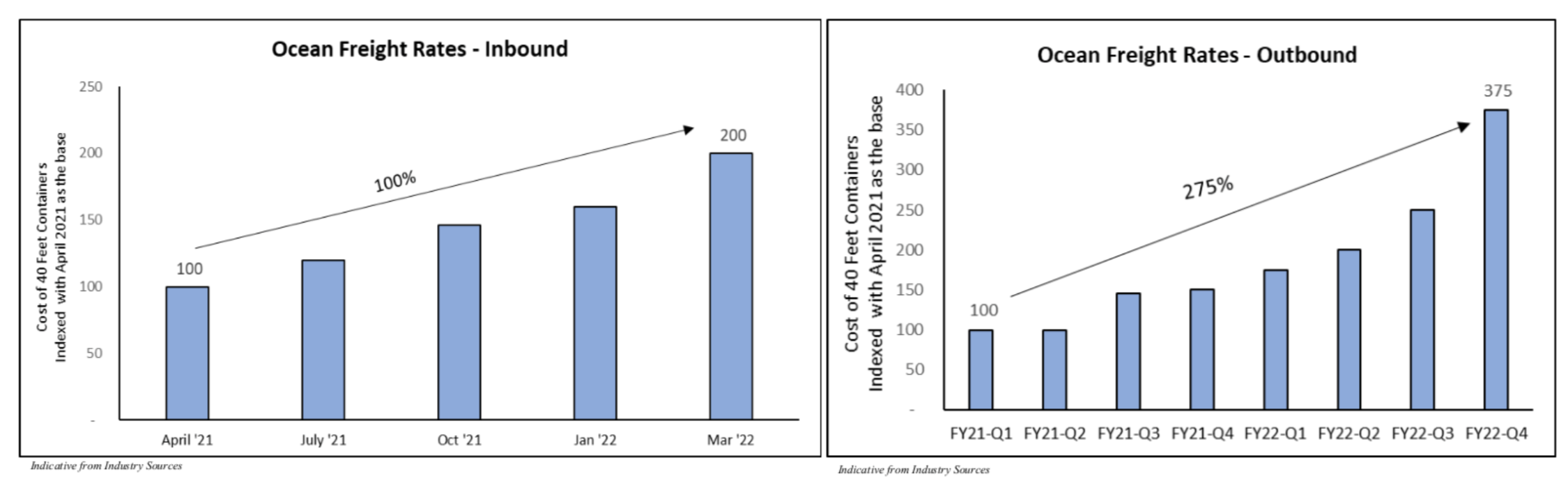

Container shortage and increasing logistics cost

Container shortage has emerged as a major challenge with the cost almost doubling in the past few quarters. According to India’s largest auto parts maker Motherson Group Chairman Vivek Chaand Sehgal, “The lead time for the container has gone up to a month from about less than a week,” he said adding that this has become a major challenge as many items are still imported from outside for the entire value chain.

“Possibly a threat to the bounce back is on the supply side constraints. These constraints arise from the semiconductor supply issues and also the logistics management. It is going to be a huge challenge this year,” says Shashank Srivastava. Increasing fuel prices have let logistics prices soar unbridled.

Sunjay Kapur, President, ACMA, said, we are always cautiously optimistic. Demand is strong. We have some supply chain issues. We hope these will get resolved sooner than later. Chip shortage continues. Investment cycle has begun. The supply chain constraints are a cyclical issue and not structural so we are staying positive and hope to overcome these obstacles.

Until there is a resolution to the geopolitical situation the cost pressure will continue to mount.

Chip shortage

Since the outbreak of Covid-19, the automotive industry supply chain has been disrupted for the worst. The main reason for the crisis was irregular production of automobiles and faster than expected recovery in some of the markets. Chip production is highly dependent on multiple geographies for its child components.

What added to the shortage due to work from home demand for computers, mobile phones and other consumer electronics during the COVID-19 pandemic increased that surpassed the current supply of semiconductors.

Maruti Suzuki India’s newly appointed MD & CEO, Hisashi Takeuchi says that chip crises will continue to be there. But he hopes that this year the situation could be better than the previous year.

Chip shortage will continue, but situation will be better than in the previous yearHisashi Takeuchi, MD & CEO, Maruti

Agreeing that the crises may linger on, Kavan Mukhtiyar, Partner and Leader – Automotive PwC India, said, “Semiconductor shortage and other supply side constraints is inhibiting higher growth and the semiconductor shortage is likely to continue over the next 9-12 months.”

Semiconductor will largely be dictated by the overall geo-political scenario and resumption of supply chains. Ukraine and Russia play a crucial role in the chip supply chain globally and in the current context we do expect some pressure on supply due to semiconductor unavailability from June 2022 onwards provided the current geo-political situation doesn’t improve.

The other area of worry is the prevailing Covid-19 situation which led to lockdown in China and some other important manufacturing hubs. For India also if the four wave leads to a lockdown which is unlikely will further impact the situation for the auto industry.

Multiple and duplicate bookings

According to Shashank Srivastava, the passenger vehicle industry has an advance booking of over 6.5 lakh units. However, the cancellation has increased in the past few months.

Another senior executive at a fast-growing car company, requesting anonymity, said, “there are multiple bookings across OEMs and models due to uncertainty in delivery, so the actual booking will not be more than 3 lakh to 3.5 lakh units. Hence, it is difficult to understand the actual demand backlog for the passenger vehicles.”