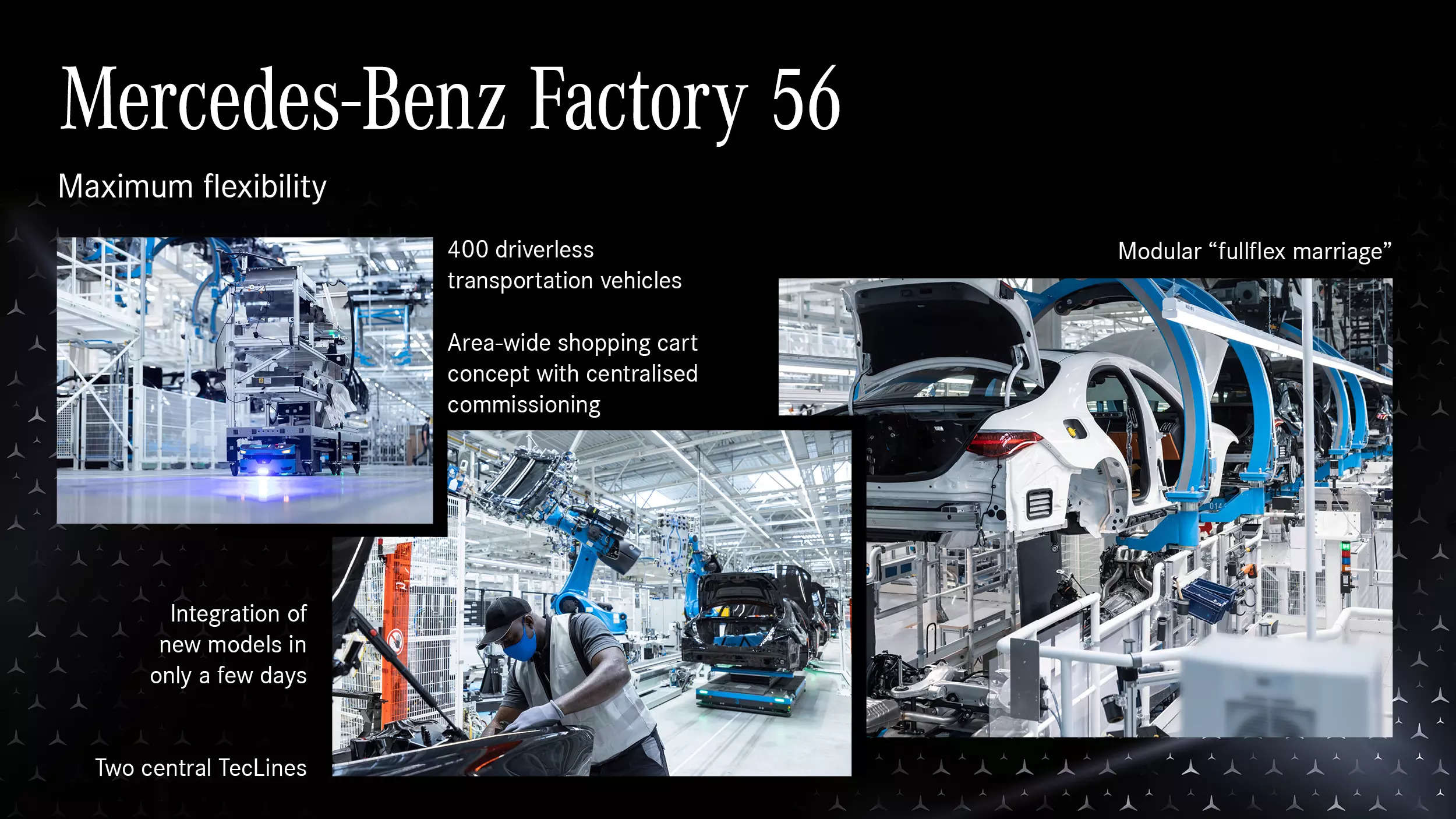

Stuttgart: As I entered the shop floor of the Mercedes-Benz’s most efficient factory here, I found myself surrounded by a number of automated guided vehicles (AGVs), moving on an unending serpentine magnetic strip crisscrossing Factory 56 which is almost equal to the size of 30 soccer grounds.

“Sometimes it is as busy in the plant as it is on the highway,” Joerg Burzer, Member of the Board of Management of Mercedes-Benz Group AG, Production & Supply Chain, said. “What you have seen here with Factory 56 is our blueprint for the production of the future,” he added.

The carmaker affirms this as the right setup to realize the big transformation which is different from its competitors. AGV, powered by heavy digitization, is the protagonist of the company’s future production.

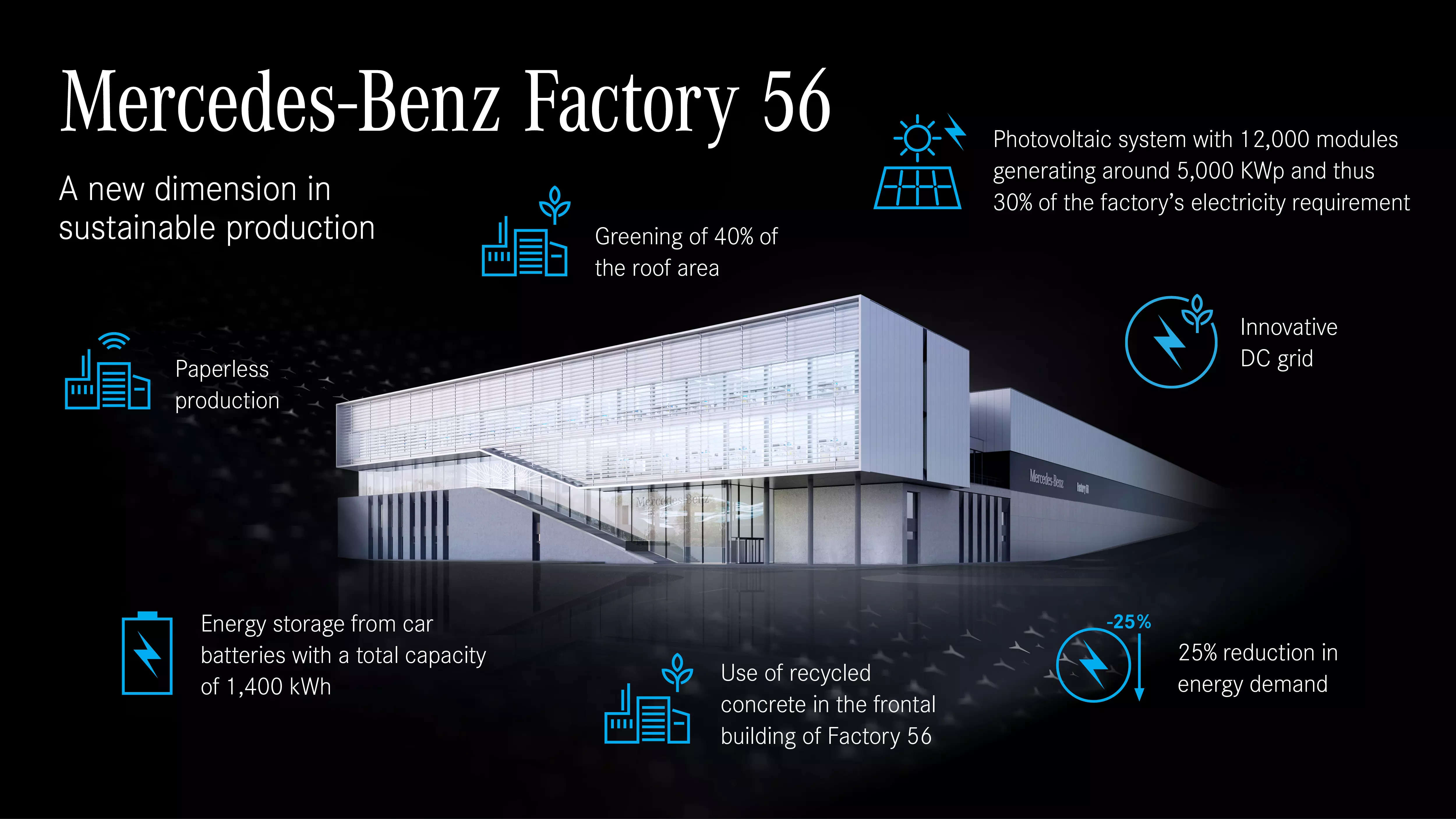

This particular factory claims to be 25% more efficient than the company’s previous most productive factory. Surprisingly, this was achieved by removing over a dozen robots and enhancing digitization, and syncing it with human resources.

The new in-house-developed digitalization setup is called MO (Mercedes Operations) 360 degree which can digitalize every production process, the company said.

The process also helps increase transparency and efficiency and keep them informed on where every part is, and if there is a quality challenge, sometimes even before it really happens.

“So we are working on this very hard. And the nice thing is, with this digitalization setup, we basically have every major update, because we do it on our own,” Burzer said.

Interestingly, even people working on the manufacturing line are skilled to do a low level of coding. This helps as they know where the challenges are and can fix them at the right time.

The factory has moved ahead of the conveyor belt and adopted the most flexible shopping cart model where thousands of AGVs of different sizes keep ferrying parts all around the assembly and manufacturing lines. The carmaker calls the transition from lean manufacturing to digital production.

“If you talk about the production of the future, what was called Lean Production in the past 10 or 15 years ago, I would call it today digital production,” Burzer said. “The focus is on enhancing HPV (hours per vehicle production) and it’s also about the number of people used in logistics. We offset a potential disadvantage of less automation with extremely high efficiency from digitalization. So that’s how we calculate it,” he said.

Burzer, who leads 75,000 team members across 34 plants, said that “soon the same level of digitization and reduction in robotic automation will be implemented in all plants.”

Digitization is not limited to internal processes only but also to the external supply chain under its Container X program. “We’re connecting our digitalization approach, not only internally in the value creation process, but also to the supply chain by managing the interface,” he said.

Fully flexible production line

The German Luxury carmaker is not building an EV-only plan. Therefore it builds all powertrain variants on one line at Factory 56. In this plant, the company has introduced a full flex marriage which is a station where body and powertrains are coming together. This feature enables them to build all powertrain variants and body type variants on one line.

In this factory, the company produces all body types and different types of powertrain vehicles, including S class and Maybach hybrid, and the EQS, on the same line. From this factory, they are serving more than 100 markets.

“So we have this pretty interesting innovation, which was launched in Factory 56, and we are in the process of launching in all plans right now,” Burzer added.

The full flex marriage feature is also going to help in terms of uncertainty on the powertrain in the future whether it is all EV or mixed one.

“So you think about it, if you have a situation in 2030 and beyond where you have an EV-only market requirement. No problem, we can do it and the full flex marriage setup. It’s not a very expensive setup but a very intelligent one. So it costs a couple of millions, but not a couple of 100 millions, which you have to spend to build a new plant,” Burzer concluded.

(The writer was in Stuttgart on the invite of Mercedes Benz AG.)

Also Read: