By Avik Chattopadhyay

The recently-concluded COP 26 deliberations in Glasgow have thrown up some very crucial questions to the growing electric vehicle (EV) industry on its role in meeting the global climate and temperature norms.

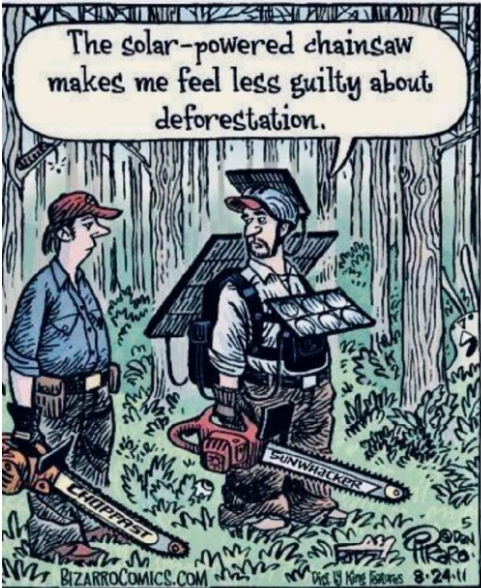

For the transition to electric mobility to be sustainable and worthwhile, it needs to be “organic” in its intent and practice. A vehicle promising zero emissions while using increasing amounts of thermoplastics for batteries, coal for electricity and diesel generator sets for components is a bit like this terrific cartoon by Dan Piraro below.

The means and the end

The term “organic” came into the limelight in the new millennium and has garnered substantial global following including in India. Applied to food products, most of us are not aware that it was developed in India in 1921 when the celebrated botanist husband-wife duo of Albert and Gabrielle Howard built the Institute of Plant Industry in Indore to combine scientific inputs with traditional Indian agricultural methods to create a blueprint for sustainable farming and food!

To be certified as organic, the means are as important as the end. Every input in the entire process of delivering a packet of organic produce must meet the stringent standards of being free of chemicals and synthetic substances. There can be no half measures.The means is as important as the end, as they actually determine the end and not vice-versa.

For an electric vehicle to truly make a positive impact on the environment, the “well to wheel” needs to be as clean as the tailpipe of the vehicle. Otherwise, it will be a self-defeating exercise possibly leading to higher emissions around us in our combined efforts to keep the vehicle green.

The ‘well to wheel’ approach

A recent report by the Council on Energy, Environment and Water [CEEW] Centre for Energy Finance estimates that it will take India close to USD 10 trillions to achieve the targeted net zero emissions by 2070. Power generation, transmission and industrial activities will account for over 90% of this projected investment. While the availability of finance is an issue, the spread and depth of the interventions and their resultant impact on the workforce is yet to be calculated.

Another report by BloombergNEF titled “Decarbonising Steel – a net-zero pathway” indicates that it will take investment of USD 278 billion by 2050 to ensure that the steel produced uses green hydrogen and not coal-fired furnaces which currently make up close to 70% of all furnaces used. Steel production globally contributes 7% of all greenhouse emissions, making it one of the biggest pollutants. The implications and impact on India’s steel industry will be far-reaching going right down the entire value chain.

Green hydrogen could be the cheapest method for steel production by 2050: BNEF

The longer India continues with coal as an input for both power generation and industrial activity, the electric vehicle being a torchbearer of zero emissions will remain a fallacy! And because the reality check says that we are still many years away from a zero-coal scenario, we should stop kidding ourselves.

Renewables and reduction, everywhere

Kristen Panerali, head of energy, materials, and infrastructure programme at the World Economic Forum, in an insightful piece in Forbes on November 4, 2021 explains “Why the electric revolution needs to be about much more than cars”. While automakers announce their EV plans, the governments need to ensure the upstream and downstream processes transition from a fossil-powered system to a green one. It is all about renewables and reduction.

The span is unfathomable right now. The cement to build a plant needs to be green. The plastic covers used on new seats at a showroom have to be removed. Currently, 80% of the global economy runs on fossil fuels.

The Energy Transitions Commission indicates that to ensure no further increase in global temperatures, tomorrow’s energy system needs to work on 68% direct electricity. While the tropical world uses up a lot of fossil fuel to be cool, the same works in the colder world to be warm. All this needs to gradually change, from the plant to the showroom to the service centre.

Need to walk the talk

Globally, automakers are making boisterous statements about their EV plans, either talking about the investments or the product portfolio. Interestingly, none are talking about how they will overhaul and upgrade their internal processes to ensure the means used are as clean as the end product. In the Indian context, this holds greater importance as the value chain right now is not very environmentally conscious. The automakers’ own operations too are subject to scrutiny.

Automakers need to demonstrate their true commitment to a greener India.Just like the entire value chain was required to meet ISO standards three decades ago, the same is expected now when it comes to energy use and production technologies. Recently, Microsoft took a bold decision to work only with organisations which demonstrate the same levels of commitment to a cleaner and greener world. Gradually, all global organisations will take similar decisions. If the Indian automaker is to be part of the global network, it will also have to comply with the same levels of demonstration.

And protect the workforce

All this will have a far-reaching impact on the reskilling and redeployment of the current workforce. Already economies are grappling with the need of less manpower to make electric vehicles. Changing consumer behaviour is also leading to role redundancies. What is happening in Canada and Germany today will happen in India and Brazil tomorrow. Coupled with a virtual lack of unionism in our country in the auto industry, the worker is surely vulnerable.

While new EV makers and their ecosystem partners [batteries, power electronics etc.] will generate fresh employment, the legacy automakers going clean will also go lean. Hence, the government’s projections of 200,000 fresh jobs from vehicle scrappage alone might not hold true if the interventions become more automated to comply with energy standards. A growing number of auto industry workers out of jobs in the next 10-15 years is one of the biggest challenges that requires collective intervention.

A kosher / halal ecosystem

In tandem with the government’s action plan of 2070, the five industry bodies of SIAM, SMEV, ACMA, ASDC and FADA need to create their collective blueprint and stage-gates towards becoming truly green eco-systems. Being 49% of India’s manufacturing GDP, the auto industry must lead the way.

Just like automakers have painstakingly worked on improving both quality consciousness and quality standards in their respective value chains, they have to now collectively work towards making them net-zero emission-compliant. The size of the industry gives it the clout to impress upon the oil / energy companies, cement and steel manufacturers, and industrial equipment makers to clean up their respective acts. The “Bonus Malus” programme in operation in France can be adapted to Indian conditions to incentivise the transformation.

The electric vehicle needs to be organic in letter and spirit to make the transition from fossil fuel energy worth all the effort. Already, global auto CEOs like Carlos Tavares of Stellantis have talked about the burden of the sheer investments needed for the same.

The carbon footprint of the entire ecosystem around the EV has to be reduced, both upstream and downstream. Only then can it claim to be cleaner than the ICE vehicle. Till then, it will be a smoking pipe!

The author is co-creator of Expereal India. Also, he is former head of marketing product planning and PR at Volkswagen India. Views are personal.

Also Read: